About

It started as a hobby...

What began as a hobby during winter months in northern Minnesota has developed into a year round business after many requests from family and friends.

Growing up in the Midwest and raised by parents with a strong work ethic I had no choice but to maintain those same qualities. I worked for a large cabinet manufacturing company, mainly in electrical maintenance for over 20 years. All the while impressed with the technology surrounding me. I had said at one time that I would like to run a CNC machine, never imagining that I would actually build my own.

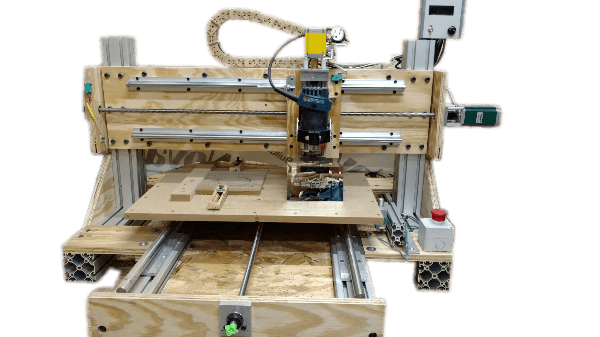

My wife and I moved to northern Minnesota in 2009. It was a dream come true for me after spending every summer vacationing here and even spending our honeymoon here. It didn’t take long to figure out that the winters are long here and you can’t fish every minute. So I started searching the internet and it wasn’t long before I built my first cnc machine. It wasn’t much, but it allowed me to figure out what it takes to make something. I have since built another larger, more rigid machine and also have a small diode laser.

I have learned a lot along the way and have made some really good new friends/mentors. I am excited to see where this takes me! Wish us luck!

My equipment

My current CNC machine, built of steel, is more rigid and much faster. This allows me to create larger custom pieces up to 50″ wide. I purchased the mechanical pieces of this one, but added all the motors, wiring and controls myself. This greatly enhances my ability to troubleshoot problems, should they arise. I can also connect my laser to the spindle to laser larger items.